Thread Engagement

Here you will see a series of images showing different states of thread engagement between a spoke and a nipple. I will discuss the desirability of each state both for ERD measurement and as the state present in a finished wheel.

The spoke is a typical 2.0mm stainless spoke. Note that the majority of common spokes (including both DT Swiss and Wheelsmith) have about 9mm of threading. This measurement will never be extremely precise, but will likely vary more than usual with no-name spokes. Because most people build with good spokes exclusively, we will be assuming this 9mm of threading to be standard and fairly exact.

The nipple is a standard 12mm brass nipple made by Wheelsmith, which has been filed in half to expose the location of the threading and the other internal dimensions. Note that nipples longer than the common 12mm will almost certainly have a different inner configuration, and will affect the theoretical ERD and therefore the calculated spoke length for a given rim. I plan to file open several other readily-available sizes of nipples for direct comparison.

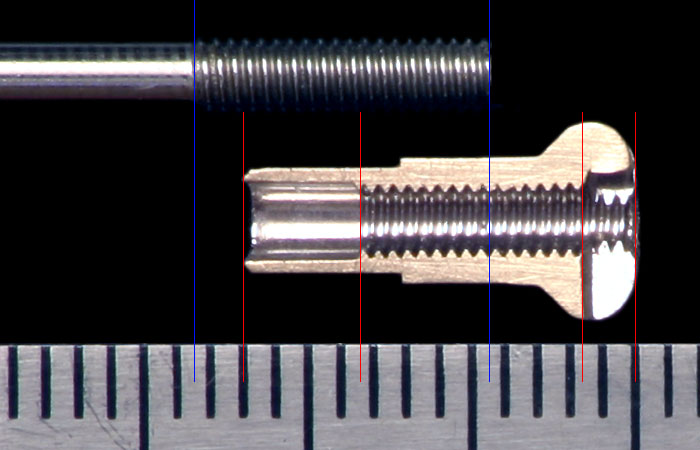

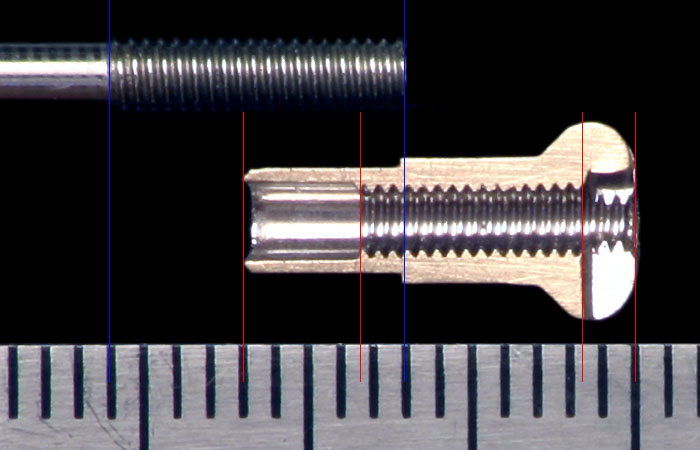

Important positions on both the spoke and nipple are highlighted with thin blue and red lines, respectively, to allow comparison on the metric ruler included in each image.

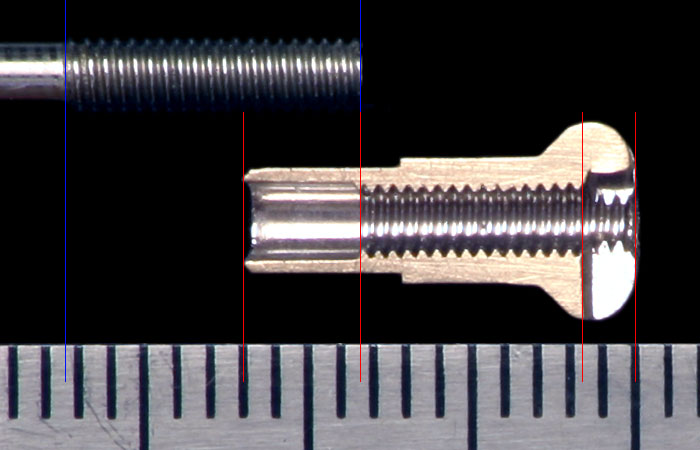

State 1: bottomed out

Thread engagement: 18 turns (100%)

Thread engagement inside head: 6 turns

This is a condition to be avoided at all costs. There is literally no further tightening adjustment possible. If the spoke is not up to adequate tension, there is nothing that can be done to fox it other than using a shorter spoke.

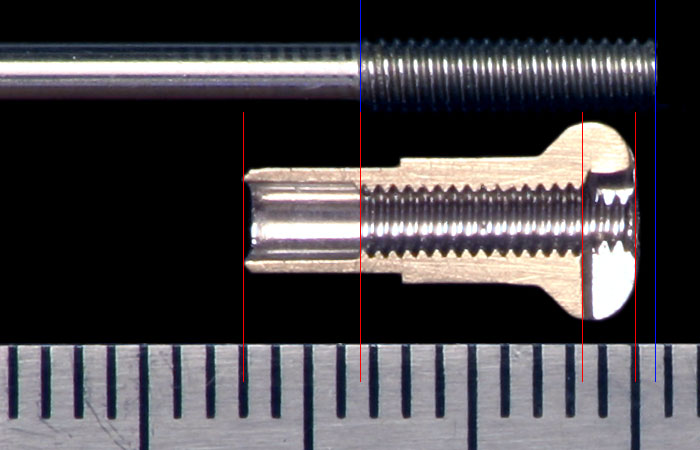

State 2: spoke end flush with head of nipple

Thread engagement: 18 turns (100%)

Thread engagement inside head: 6 turns

Many people use this position for ERD measurements, and therefore the spokes in their finished wheels will be in roughly this same state. Notice that there is only about 0.6mm of tightening adjustment possible before bottoming out. It's a real bummer to be truing a wheel and run into spokes that have bottomed out and can't be tightened, which is why I don't recommend this. If you do want to achieve

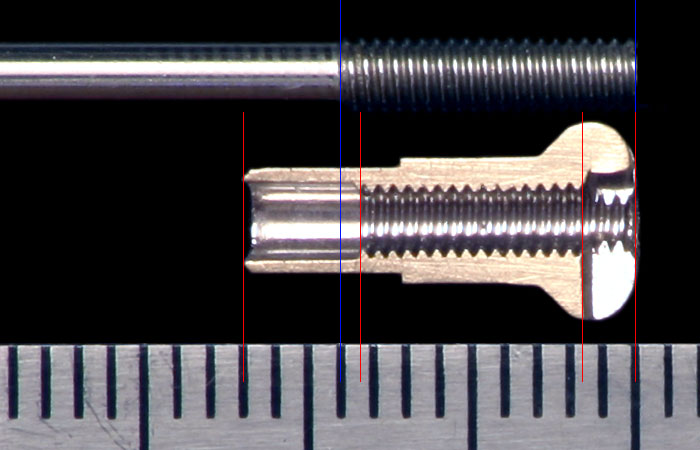

State 3: spoke end flush with bottom of screwdriver slot

Thread engagement: 15 turns (83%)

Thread engagement inside head: 3 turns

I strongly believe that this is the ideal amount of thread engagement, and use this exclusively when measuring the ERD of rims. There is about 2.2mm of tightening adjustment possible before bottoming out, yet there are still 3 turns of thread engagement above the nipple seat to provide the nipple with more resistance against breaking right at the seat. This is especially important when building with aluminum nipples, since they are much more succeptible to breaking at the seat than brass nipples. (a good arguement to avoid aluminum nipples altogether)

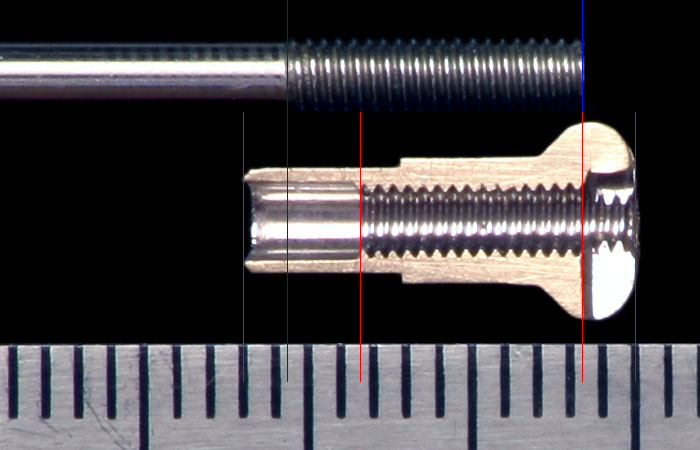

State 4: no threads exposed

Thread engagement: 12 turns (67%)

Thread engagement inside head: none

State 5: three threads exposed

Thread engagement: 9 turns (50%)

Thread engagement inside head: none

State 6: only three threads engaged

Thread engagement: 3 turns (17%)

Thread engagement inside head: none

State 7: no threads engaged

Thread engagement: 0 turns (0%)

Thread engagement inside head: none